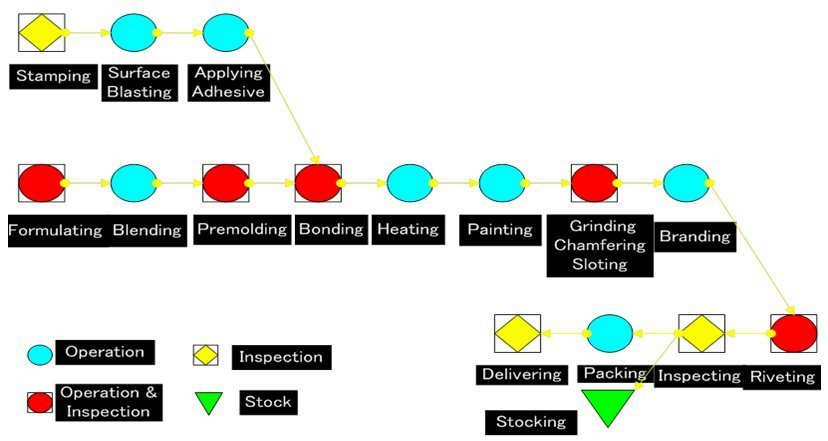

Handling of the Backing Plate

Step B1 - Stamping of the Backing Plate

Stamp the backing plate form high-grade steel into the exact design shape to fit vehicle caliper.

Step B2 - Surface Blasting

Roughen the surface of backing plate for increasing the adhesion to avoid material breaking

away from the backing plate.

Step B3 - Applying the Adhesive to the Surface

Apply the adhesive to the backing plate and get ready to bond the friction materials.

The Main Process

Step A1 - Formulating the Raw Materials

Each brake pad contains several friction materials of the highest quality for better performance

and long life.

Step A2 - Blending the Friction Materials

Blend the materials to meet the detailed formulations so that the performance of the brake pad

will be extended widely.

Step A3 - Molding the Materials

Mold the unique formulations under extreme temperatures and pressure into the shape of bricks.

Step A4 - Bonding

Bond firmly the friction materials to the backing plate under immense heat and pressure.

Step A5 - Heating

Heat the unfinished pads in the heating processor for 8 ~ 10 hours to the everlasting attachment.

Step A6 - Painting

Painting embellishes the appearance of the brake pads and protects them from rust and corrosion.

Step A7 - Grooving, Chamfering and Grinding

With the lathe of triple foundations- grooving, chamfering and grinding, it not only reduces brake noise

for quieter operation but also improves friction levels.

Step A8 - Branding

Branding our unique brand and accurate part number ensures that the right pad is fit in the right car.

Step A9 - Riveting

Riveting sensors can exactly tell drivers when their pads are worn below safe limits.

Step A10 - Inspecting

Meticulously check on the finished brake pads before packing to ensure the safety of products.

Step A11 - Packing

After shrink-wrapping, each brake pad set is singly packed in a cardboard to assist with storage,

transportation and the sale of the products.

Step A12 - Storing

Storing the products in our own warehouse makes certain our endlessly sufficient supply. |